Project Information

- Year 2024

- Duration 36 mois

- Location Grand Est

- Project Leader CRITT Matériaux Innovation

-

Partners

- UTT (Troyes)

-

Co-funded by

- Institut CARNOT ICÉEL

- Institut CARNOT MICA

- Sector Additive Manufacturing

Project Description

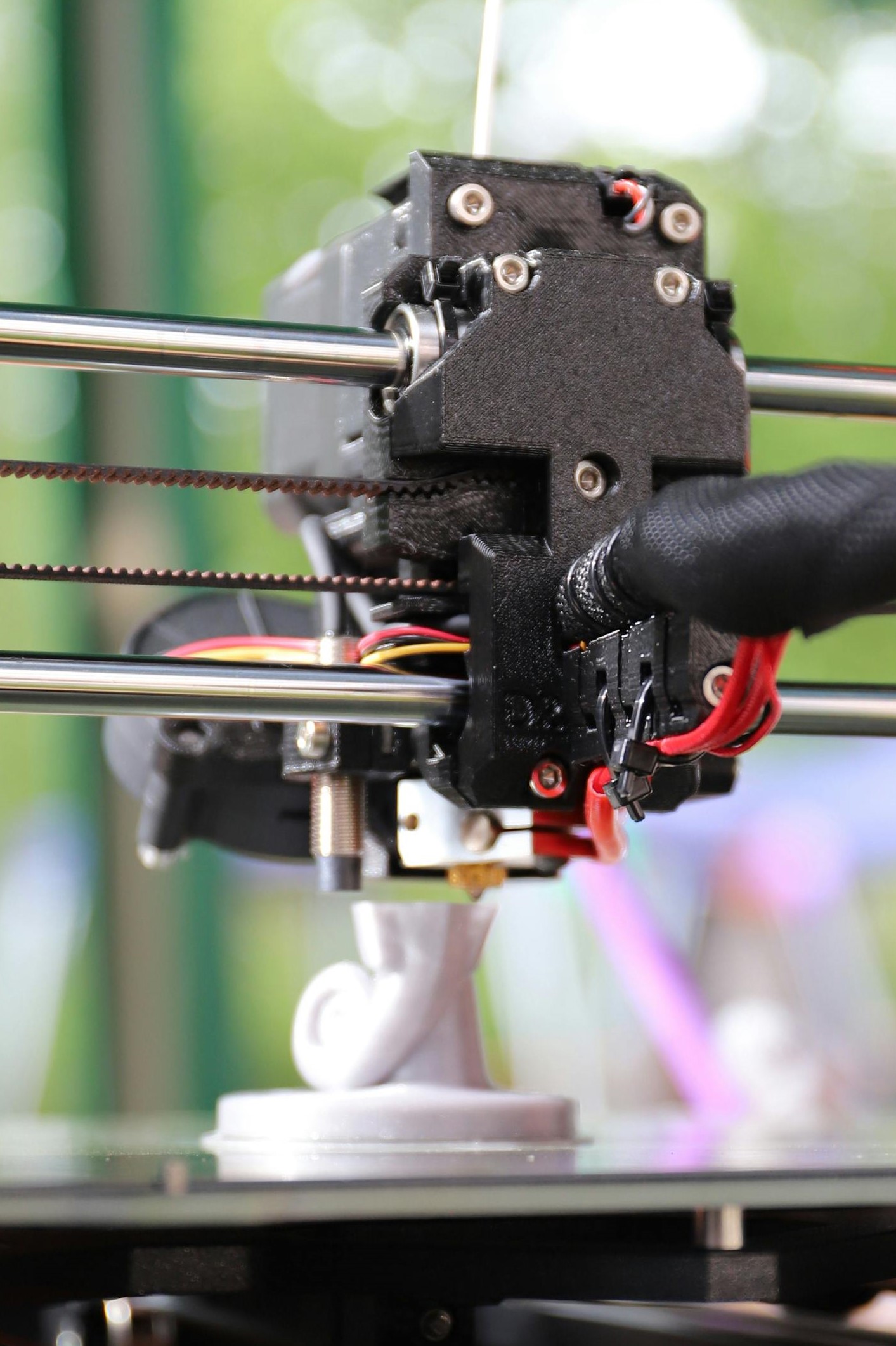

Metal additive manufacturing: Development of 3D printing using Bound Powder Extrusion (BPE)

CRITT MATÉRIAUX INNOVATION, a COFRAC-accredited and NADCAP-certified laboratory, is leading the TEAM project in partnership withUTT (Troyes). This industrial research project aims to develop3D metal printing by extrusion of hot polymers filled with metal powder, known as " Bound Powder Extrusion (BPE) ", applied to new tool steels for industry.

BPE technology represents a major innovation in additive manufacturing: it combines the advantages of polymer 3D printing (geometric freedom, low cost) with the mechanical properties of metal parts after debinding and sintering. This approach opens up new prospects for the aerospace, automotive and industrial tooling sectors.

Innovation and novelty of the project

To date, no research work has been published on BPE-printed tool steels combined with comprehensive metallurgical and mechanical characterizations. CRITT Matériaux Innovation is contributing its unique expertise in metallurgy, material characterization and surface analysis to overcome the scientific and technical hurdles.

Another original aspect is that we will be using both open source (flexibility, customization) and proprietary (industrial performance) 3D printers, enabling a comparative approach and multi-scale validation.

Technical objectives of CRITT Matériaux Innovation

- Overcome the technological limits of BPE additive manufacturing for tool steels

- Control manufacturing parameters: extrusion temperature, printing speed, fill rate, etc.

- Develop a complete characterization protocol: metallography, mechanical testing, surface analysis

- Optimize debinding and sintering cycles to obtain optimum mechanical properties.

Technical resources and platform

The project mobilizes the entire CRITT Matériaux Innovation technology platform based in the Grand Est region (Charleville-Mézières and Nogent):

- BPE 3D printing: open source and proprietary printers dedicated to metallic materials

- Post-treatment equipment: Thermal and catalytic debinding furnaces, controlled atmosphere sintering furnaces

- Metallography laboratory: sample preparation, optical and electron microscopy (SEM)

- Mechanical characterization: tensile tests, Vickers/Rockwell hardness, impact strength

- Surface analysis: 3D roughness measurement, profilometry, residual stress measurement (SMAT)

- Chemical analysis: Spectrometry for alloy composition control

Project progress and phases

The project is divided into 4 key phases over 36 months:

- Phase 1 - Formulation development: Optimization of metal powder/polymer binder mixtures

- Phase 2 - Printing and optimization: Tests on open source and proprietary printers, definition of optimum parameters

- Phase 3 - Post-treatment: Development of debinding and sintering cycles, characterization of parts

- Phase 4 - Industrial validation: Manufacture of demonstrator parts, testing in real-life conditions, transfer to manufacturers.

Impact for the Grand Est industry

This project positions CRITT Matériaux Innovation as a reference in metal additive manufacturing in the Grand Est region. The results will enable regional manufacturers (tooling, mechanics, aeronautics) to access an accessible, high-performance additive manufacturing technology, reducing costs and development times for complex metal parts.

Challenges & Issues

- Maîtriser les paramètres de fabrication pour cette nouvelle technologie