Collaborative projects

CRITT MATÉRIAUX INNOVATION is continously involved, as leader or partner, in about ten R&D or technological diffusion collaborative projects.

It’s one of its main missions, which allows resource continuously its staff, be active and recognized in European scientific nets and propose innovative solutions for its industrial customers

Our projects

Collaborative projects

CRITT MATÉRIAUX INNOVATION is continously involved, as leader or partner, in about ten R&D or technological diffusion collaborative projects.

It’s one of its main missions, which allows resource continuously its staff, be active and recognized in European scientific nets and propose innovative solutions for its industrial customers

Our projects

CARNOT MICA TEAM

Project leader :

Partners :

Project co-funded by :

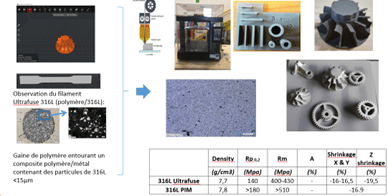

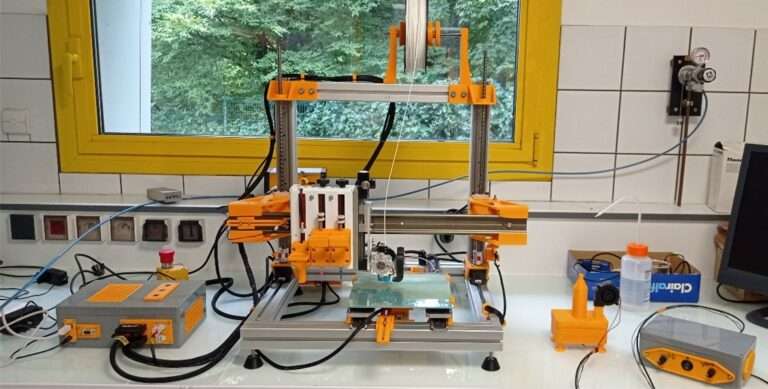

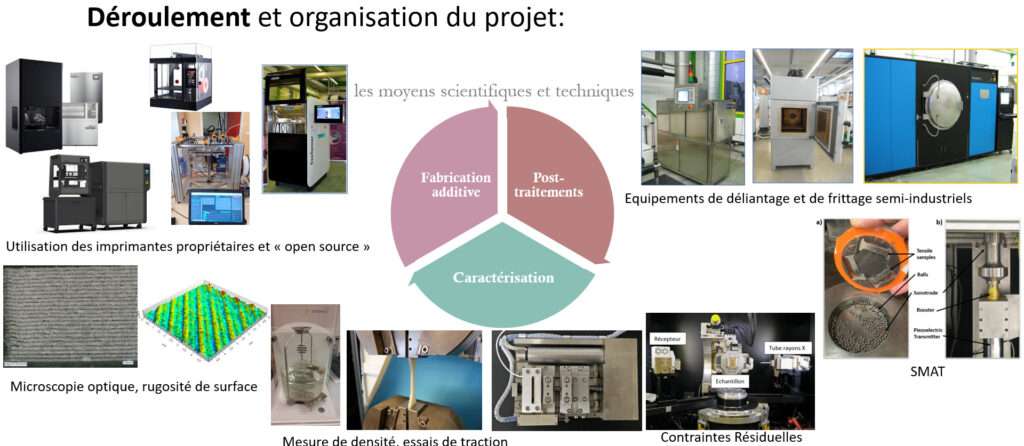

TEAM aims to develop extrusion printing of hot polymers loaded with metal powder, known as “Bound Powder Extrusion” (BPE), focused on new tool steels. Both the manufacturing processes and the transformed materials used in this project are innovative. Up to now, few research has been published on tool steels printed by BPE in conjunction with metallurgical and mechanical characterization. The originality also lies in the fact that we will use both open-source and proprietary printers. Thus, the project aims to overcome usage limitations, master manufacturing by proposing an experimental characterization protocol, and also investigate the surface reactivity issues of these new materials.

CORTHEMIS

Project leader :

Partners :

Projet co-funded by :

The aim of the CORTHEMIS project is to study the corrosion and thermal properties of innovative materials and promote solutions that can be transferred to industry, particularly in the Grand-Est region, by building on the results of the MATREX 2 project carried out by the consortium of 4 partners over the period 2020-2022. Indeed, the work to be carried out in CORTHEMIS should anticipate the scarcity of certain materials and provide manufacturers with alternative solutions for shaping highly stressed parts to reduce their replacement. The stakes are both strategic and environmental, in the context of energy savings and resource scarcity. To this end, three main avenues of improvement are envisaged within the scope of the work:

1. Lubrication-free glass mold installation thanks to new tool geometries, materials and coatings

a) Self-lubricating materials: improved environmental conditions to produce spressed glass parts by reducing or eliminating the need for lubrication.

b) Durability: minimizing tooling costs for medium production runs.

2. Strengthening tooling for hydrogen-powered engines, automobiles and glass by developing new materials and coatings solutions for intensive use.

a) Development of forging tools for new hydrogen engines

b) Development of new chemical diffusion barriers

3. Additive manufacturing, new solutions in the healthcare and aeronautics sectors for complex ceramic parts that cannot be produced using other processes.

a) The use of alumina in 3D printing to study thermal barriers,

b) 3D printing and sintering of silicon carbide

The three approaches studied as part of the CORTHEMIS project will culminate in the production of test parts representative of the target markets. The solutions developed will enable manufacturers to address new markets for highly stressed material applications, notably in the glass, foundry, forging, aerospace and medical sectors.

SURFACESplus

Project leader :

Partners :

Project co-funded by :

Manufacturers in the Grand Est region are facing up to the challenges posed by the strategic issues of the France 2030 plan, as set out in the BAGE and the smart specialization strategy (S3). Becoming the leader in green hydrogen; Decarbonizing industry; Producing nearly 2 million electric and hybrid vehicles; Creating the medical devices of tomorrow, are among these objectives, which share the urgent need to develop new high-performance materials.

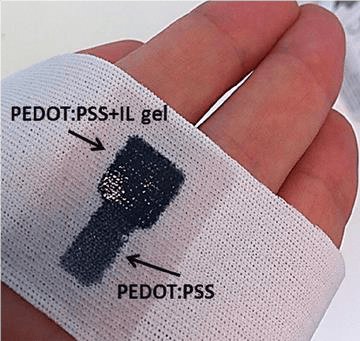

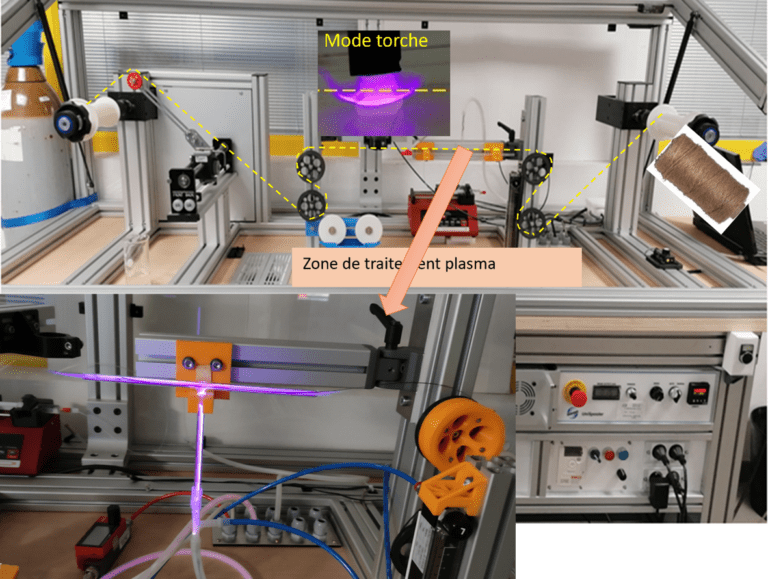

The SURFACESplus resourcing project aims to develop original surface functionalization solutions for the creation of innovative, high-performance materials that conduct electricity and react with their environment. The proposed resourcing strategy is based on a collaborative approach involving the cross-fertilization of partners’ skills and industrial processes: CRITT TJFU’s Cold Spray, as well as supercritical nitrogen and high-pressure waterjet, CRITT MI’s Plasma, CERFAV’s GLAM, and the pooling of their characterization methods and resources.

SURFACESplus partner CRTs specialize in the design and implementation of advanced functions that can be integrated into surfaces, such as exchange properties with the surrounding environment, to enable :

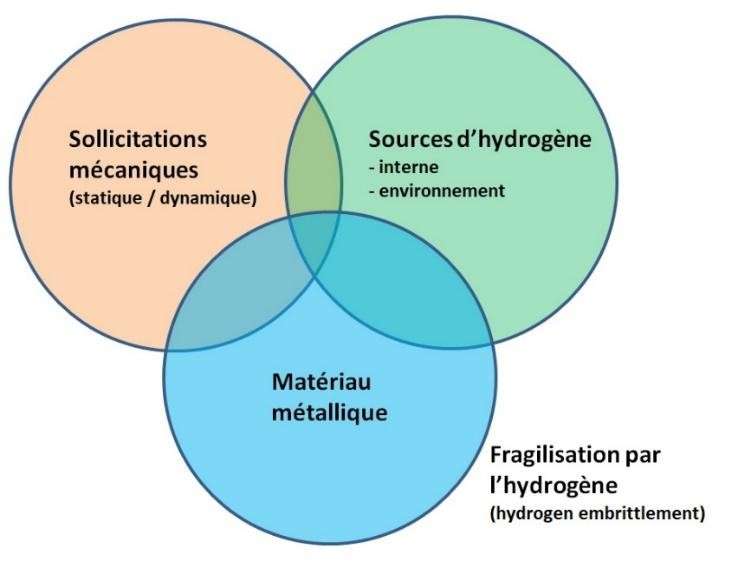

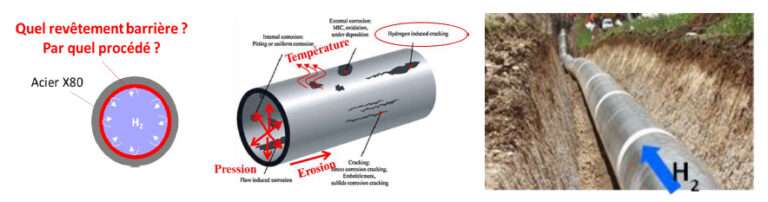

– combat embrittlement of hydrogen transport pipelines by the H2 molecule

– promote the electronic and protonic conduction of a polymer membrane in H2 fuel cells and Li-Ion batteries

– design flexible electrodes for biocompatible connected textiles (healthcare, medical devices, bioelectronics)

– combating bacterial colonization in the osseointegration of orthopedic prostheses.

ANR Project PIMyBone

Project leader :

Partners :

Program co-funded by :

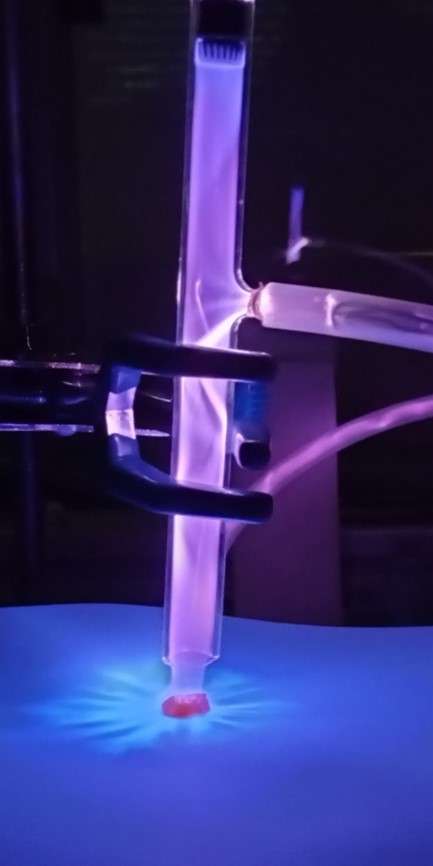

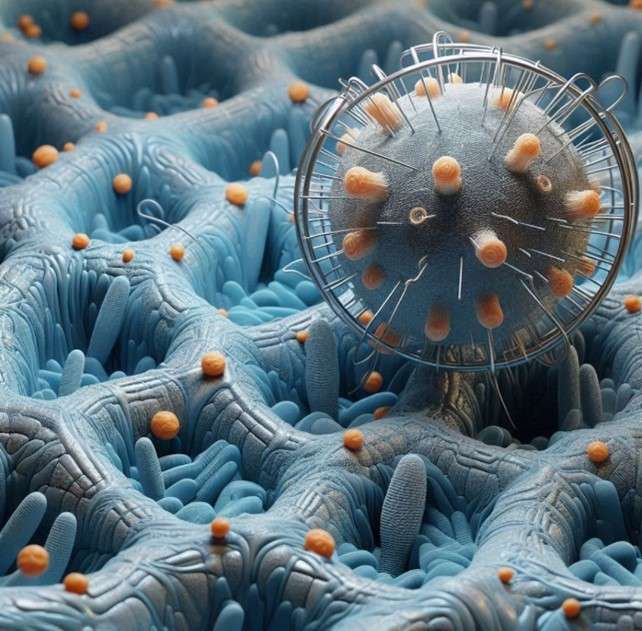

With population ageing worldwide there is a constant increase in need for bone filling material in order to treat critical bone defect. Actually long bone defects are particularly challenging for regenerative medicine. To date no adequate scaffold able to promote tissue ingrowth within such a context is available. The current synthetic bone substitutes have a weak capacity to stimulate the neo-tissue formation, to limit the risk of infection and can induce an inflammation deleterious for the durability of the implant.

Moreover, ceramic substitutes are naturally brittle and with limited ergonomics which make them difficult to use in certain conditions (various anatomical sites: access, geometry and mechanical stress). The ionic doping of porous bioceramics based on calcium phosphates (CaP) could be used to overcome the first difficulties mentioned, using strontium (Sr), copper (Cu) and zinc (Zn) respectively, while the use of a interlocking or breakable ceramic scaffold as a biobased shape memory composite could make it possible to overcome the second limitation.

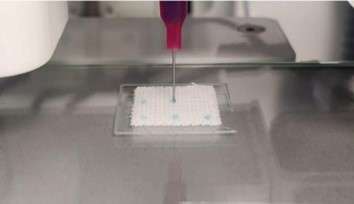

Thus, our PIMyBone program aims to develop, characterize on the physicochemical and mechanical levels, and to evaluate biologically (in vitro and in vivo) two therapeutic solutions via macroporous scaffolds either ceramic or hybrid ceramic / shape memory composite.

These three-dimensional structures will be shaped by the same optimized PIM (Powder Injection Moulding) process using additive manufacturing tools, in order to obtain complex custom geometries with multiple porosity levels, to allow use in any indication and regardless of the geometry of the bone defect.

ACHEVALD

Porteur du projet :

Partenaires :

Programme cofinancé par :

The challenge of the ACHEVALD project is to get manufacturers to replace the hard chromium plating technique (or hexavalent chromium plating), which is classified as carcinogenic harmful to the environment and covered by REACH REGULATIONS. To this end, the ACHEVALD project offers a range of 4 green technologies to meet a wide range of needs:

- The wet deposition: chemical and electrolytic deposition

The ACHEVALD project proposes to innovate deposits from a nickel matrix by including hard and/or self-lubricating particles

- The dry deposition: plasma and laser thermal spray deposition

The ACHEVALD project is developing an innovative chrome deposit to meet industrial needs.

This will enable companies to maintain their economic activity with sustainable and ecological solutions. For each technology, we will support at least one company in testing and validating these new deposits in line with its requirements. The Life Cycle Assessment (LCA) study, which will be carried out as part of the project, will help to orient and optimize the proposed alternative solutions so that they adhere as closely as possible to the principles of the circular economy, which aim to reduce waste, promote recycling and encourage the efficient use of resources. In addition to technical support, the project will provide companies with theoretical and practical training on the 4 solutions available to them. This will enable the project to be communicated in an educational way, targeting a wide audience (industry and students). The project will also provide manufacturers with advice, support for implementation, technology watch and state-of-the-art studies.

Start date: 01/04/2024

End date: 31/03/2028

Total budget: 1.757 K€

ERDF funding: 1.054 K€

TECH4FAB

Project leader :

Partners :

Project co-funded by :

The TECH4FAB project aims to strengthen the resilience and agility of industrial value chains, meeting the challenges of manufacturing technologies, metallurgical processes, environmental management, and energy solutions. Using advanced manufacturing processes, including additives and hybrids, the project develops technologies to improve efficiency, reduce costs and integrate new functions.

The R&D demonstrators, divided into four themes, serve as test beds for technological innovations (TRL 7/8). Cross-border collaboration will speed up developments, and adoption of these technologies to strengthen the sustainability of the industrial ecosystem.

Start date: 01/07/2024

End date: 30/06/2028

Total budget: 3.552 K€

ERDF funding: 2.131 K€

AGILITY

Porteur du projet :

Partenaires :

Programme cofinancé par :

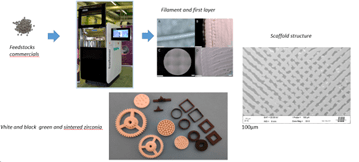

This project aims to support companies through innovation and applied research in the field of additive manufacturing of technical and filled polymers for maintenance applications and rapid tooling production.

The CRITT Materiaux Innovation center brings its expertise in the following tasks:

- Materials: Developing formulations adapted to additive manufacturing, particularly with metallic or ceramic fillers.

- Additive Manufacturing Processes: Developing new printing strategies, new tools, and accessories, etc.

- Post-Processing: Debinding and sintering processes to produce printed tools made from ceramics and metals.

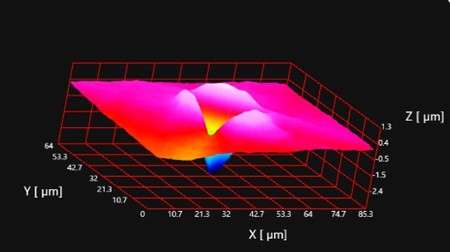

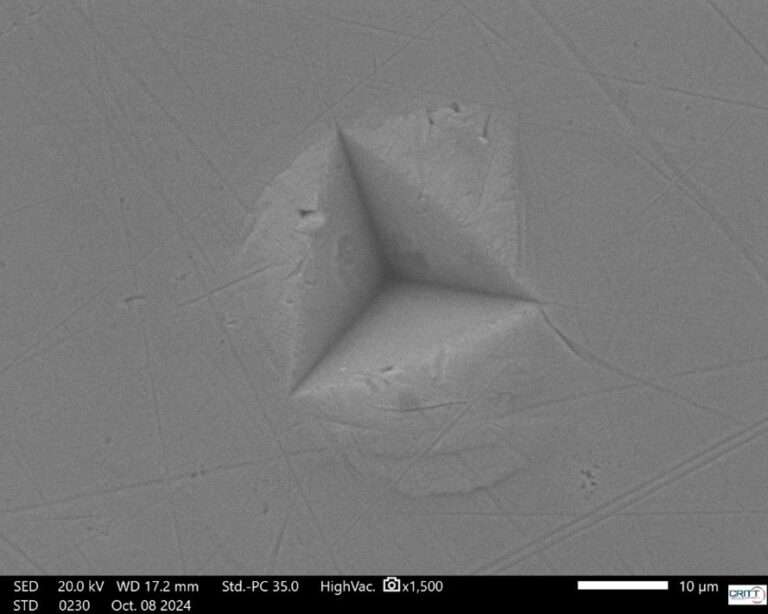

- Material Characterization: Characterizing metallic or ceramic materials, including microscopy analysis, roughness measurements, mechanical property testing, chemical analysis, and material health assessments to validate the materials according to the requirements defined by the targeted industrial applications.

Start date: 01/04/2024

End date: 31/03/2028

Total budget: 2.992 K€

ERDF funding: 1.795 K€

AntiRési

Project leader :

Partners :

Projet co-funded by :

The AntiRési project represents a proactive and innovative response to the issue of antibiotic resistance by implementing a cross-border approach that brings together operators from the France-Wallonia-Vlaanderen area to develop effective, sustainable, and economically viable antibacterial solutions. This project will help strengthen the research and innovation capacities of the region and support economic growth while improving public health.

The objectives of the AntiRési project are as follows:

- Propose technological innovations and alternatives: Develop innovative solutions to limit antibiotic resistance, taking into account socio-economic and health challenges, as well as cost and sustainability constraints.

- Diversify antibacterial solutions: Partners aim to broaden the arsenal of solutions by exploring different methods and modes of antibacterial action.

- Master new processes: The project includes the development of efficient production and implementation processes for the new solutions.

- Disseminate innovative methods to social actors: ANTIRESI proposes innovative methods to social actors, including businesses, healthcare institutions, and public authorities, to address the threat of antibiotic resistance.

Three types of deliverables are envisioned for this project:

- A specific case study around three types of materials: ceramics, metals, and polymers/fabrics. These case studies will lead to the creation of effective antibacterial surfaces, opening new perspectives for various applications. Over the four years of the project, the development of specific materials produced by companies in the region (and marketed in the region and more broadly in the European and international markets) with improved properties will result in comprehensive and qualified systems (TRL 8).

- The implementation of a Network of Excellence, comprising the project operators, which will promote collaboration and knowledge sharing to accelerate the development of antimicrobial solutions.

- The development of a methodological guide, which will describe best practices for the design, manufacture, and use of solutions to enhance antibacterial properties, categorized by sector. This guide will be made available to economic and societal actors to assist them in adopting these new technologies.

Start date: 01/07/2024

End date: 30/06/2028

Total budget: 3.481 K€

ERDF funding: 2.089 K€

COMPOVERT

Project leader :

Partners :

Project co-funded by :

The aim of the COMPOVERT project is to develop cross-border functional composite materials with plant-based reinforcements, in particular through the valorization of local (sub)products such as lignocellulosic fibers and lignin.

The development of recyclable biocomposites with original antioxidant, anti-bacterial or anti-static properties will broaden the scope of applications to meet the specifications of manufacturers throughout the France-Wallonia-Vlaanderen cross-border area.

CRITT-MI will focus on plasma-assisted physicochemical treatments for functionalizing plant-reinforced composites.

Start date : 01/04/2024

End date : 31/03/2028

Tobal budget : 2.930 K€

ERDF funding : 1.758 K€

SAFE

Project leader :

Partners :

Project co-funded by :

Biomaterials are used to manufacture medical implants, particularly those used in orthopaedic surgery (screws, plates, etc.), vascular surgery (stents, etc.) and dental implantology (screws, abutments, etc.). They are used to replace a lost or diseased biological structure to restore a function or a shape. In this way, biomaterials are going to improve the quality of life of an ageing population. Ti implants are widely used in the dental field, where they are faced with real clinical problems linked to the slow biological response on their surface, slow osseointegration and bacterial colonisation leading to loosening of the implant and therefore its loss of viability. The Ti biomaterial is a substrate that allows bacterial-surface interactions and microbial accumulation that can lead to implant failure, necessitating its removal, generating serious oral health problems for patients and impairing their quality of life. The performances requirements for implants are suitable mechanicals properties, controlled resistance to corrosion in biological environments, antibacterials properties and an adequate biological response. Surface modifications are therefore required to optimise their functionals properties.

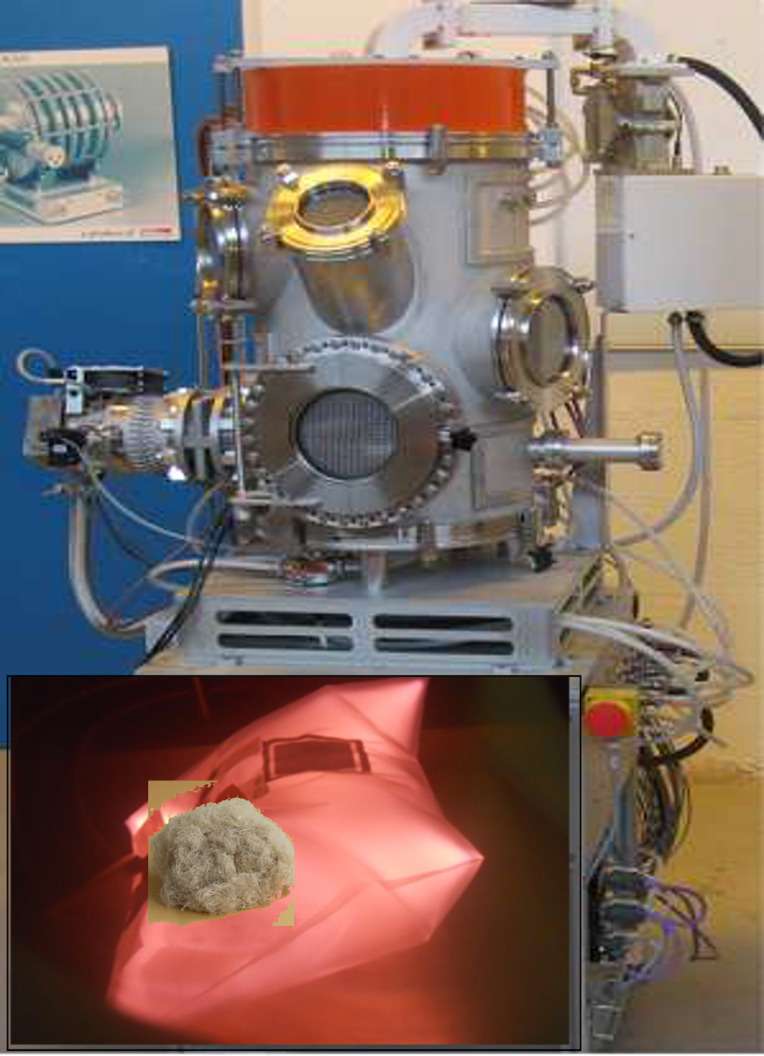

In this context, the innovation brought by the SAFE project is the development and combination of plasma and dry surface treatment technologies to optimize the microstructure and the nanostructure of the surface (in Ti) to meet the specifications required by clinicians and hospitals and to move forward in the development of biomaterials. The proposed combination of plasma technologies has not yet been envisaged in previous projects and could lead to a TRL of 3 to 7 for Titanium dental implants and an endoscopic device. To achieve this objective, this project can count on the complementary expertise of his cross-border teams. This following team include experts in wet and dry process technologies (UMONS, UGent), in technology and performance upscaling (Materia Nova, CRITT), and in-depth characterisation (ULille, UPHF, Materia Nova and UMONS). These skills can be be found, in one hand, on the Belgian border for the developments one, and on the other hand on the French side for the characterisations one. This meeting of cross-border expertise is a remarkable opportunity to innovate in the field of implants by developing new deposition and characterisation technologies that can then have a significative impact on the target audiences in the Interreg zone (companies, clinicians, scientists and the patients). The SAFE project will also provide the medical and industrial communities with a technological platform for characterisation that will help them to develop new biomaterials and disseminate the results of the research thanks to the partnership initiated with the associated operators (CHULille, CH EpiCura, CHU Helora, UZGent, BioWin, etc.). The beneficiaries of this project will be the ageing population or those subject to fractures, hospitals through the development of more effectives implants that meet their specifications, SMEs through the provision of a technological platform and privileged contact with users, and operators through the broadening of their field of expertise.

Start date: 01/10/2024

End date: 30/09/2028

Total budget: 2.810 K€

ERDF funding: 1.686 K€

© 2025 CRITT MI – All rights reserved – Legal notice

9 rue Claude Chrétien, Campus Sup Ardenne, Bâtiment D, 08000 Charleville-Mézières | 26 Rue Lavoisier, Pôle Technologique de Champagne, Bâtiment A, 52800 Nogent