Analysis and testing

The labs of CRITT MATÉRIAUX INNOVATION offer you all means need to determine chemical composition, mechanical and tribological properties, corrosion endurance, on the core or surface of your parts or samples

Wearing and rubbing testing Mechanical testing Ageing testing Chemical analysis

Analysis and testing

The labs of CRITT MATÉRIAUX INNOVATION offer you all means need to determine chemical composition, mechanical and tribological properties, corrosion endurance, on the core or surface of your parts or samples

Wearing and rubbing testing Mechanical testing Ageing testing Chemical analysis

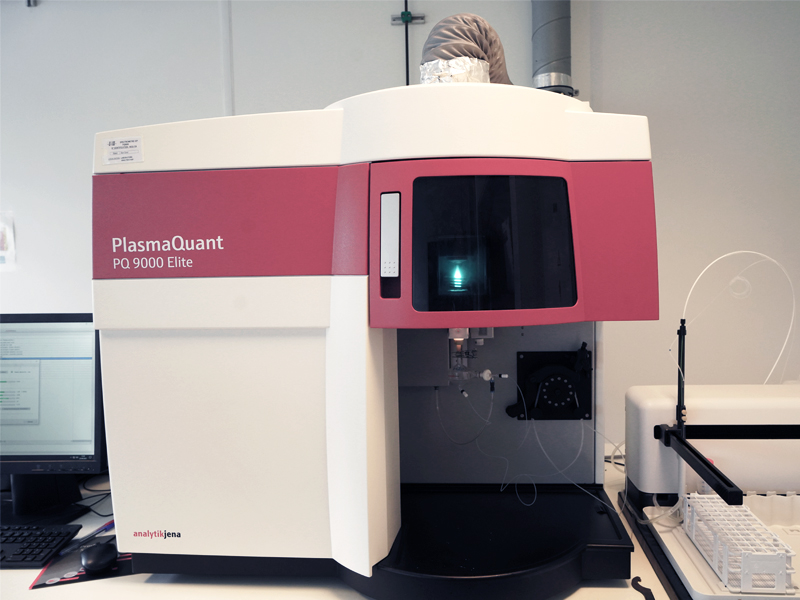

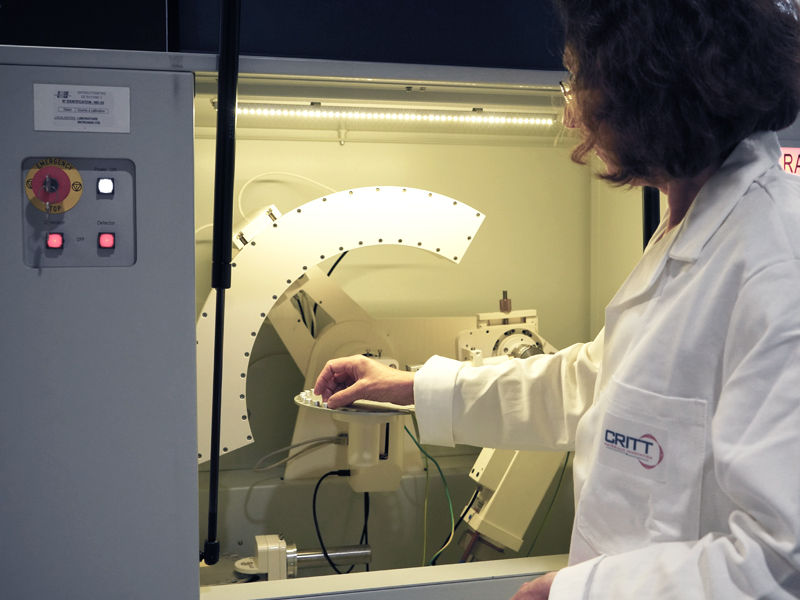

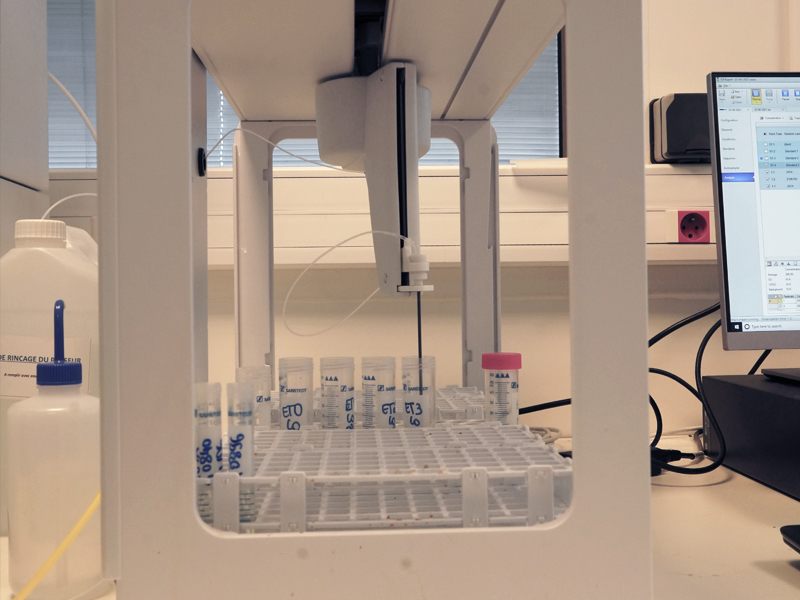

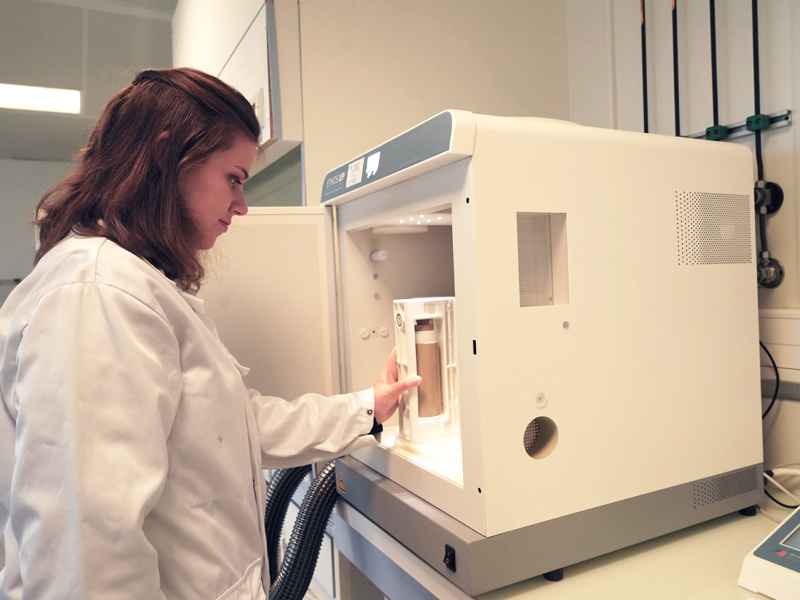

Chemical analysis

analysises

Chemical analysis and micro analysis lab of CRITT MATÉRIAUX INNOVATION offers very complete skills and facilities for chemical element dosing, core or on surface, for all kind of materials or samples.

A large part of the chemical analysises carried out by CRITT MATÉRIAUX INNOVATION can be performed under NF EN ISO/IEC 17025 (COFRAC) or NADCAP accreditation, or AIRBUS or SAFRAN qualification. See detail here

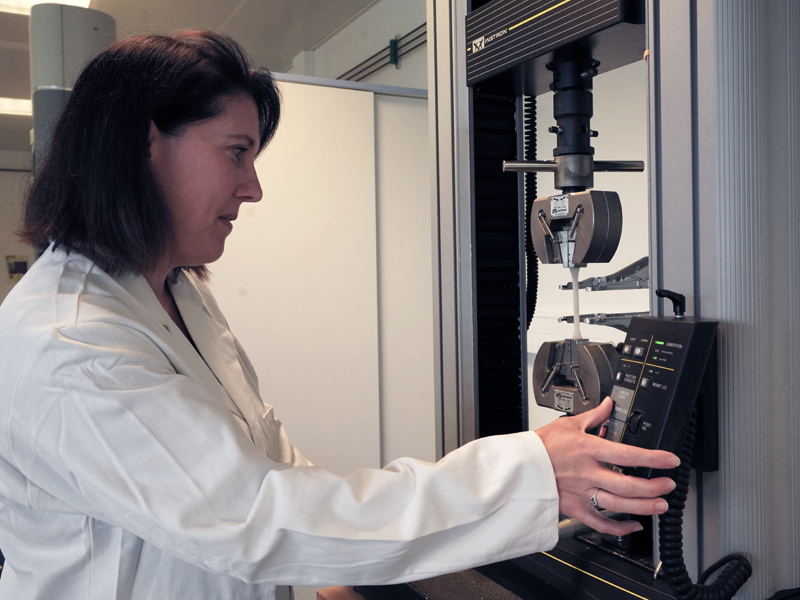

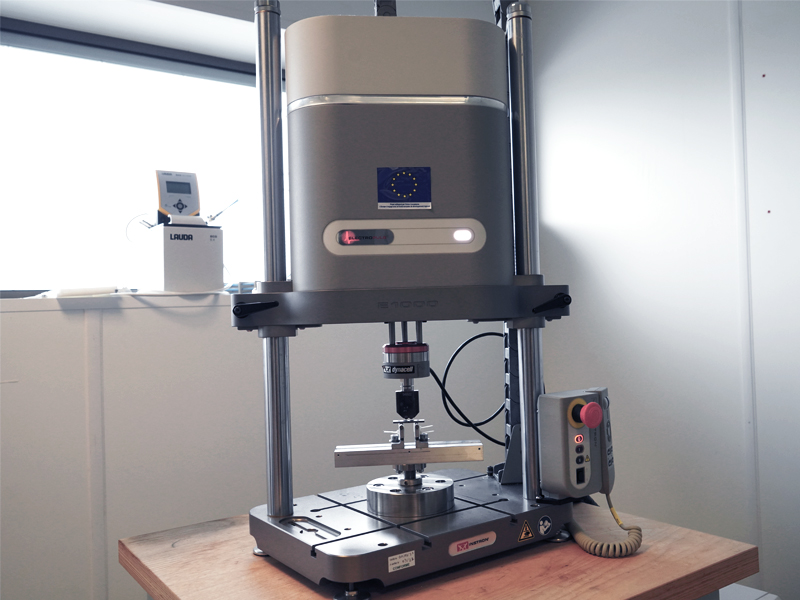

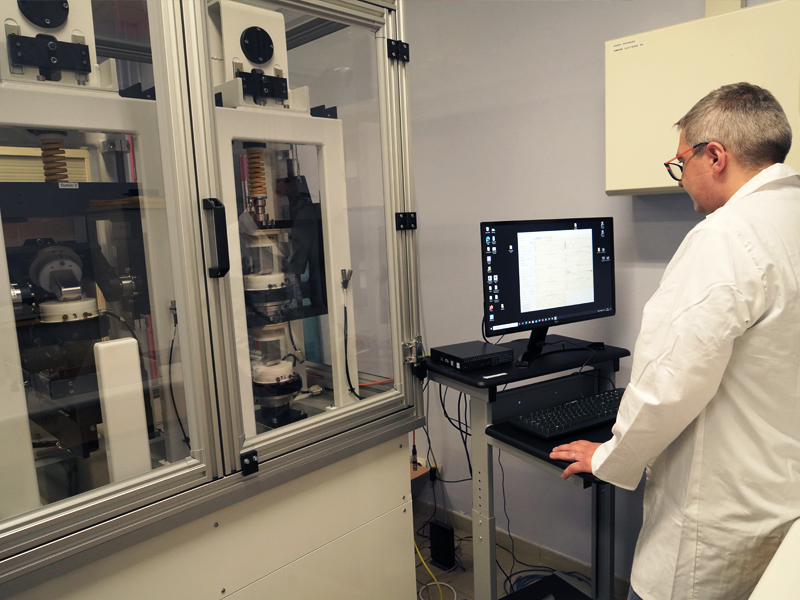

Mechanical testing

mechanical tests

The mechanical testing lab of CRITT MATÉRIAUX INNOVATION have a pool of machines which can perform a large tests range, according with existing standards or protocol adapted for your request :

A large part of the mechanical tests carried out by CRITT MATÉRIAUX INNOVATION can be performed under NF EN ISO/IEC 17025 (COFRAC) or NADCAP accreditation, or AIRBUS or SAFRAN qualification. See detail here.

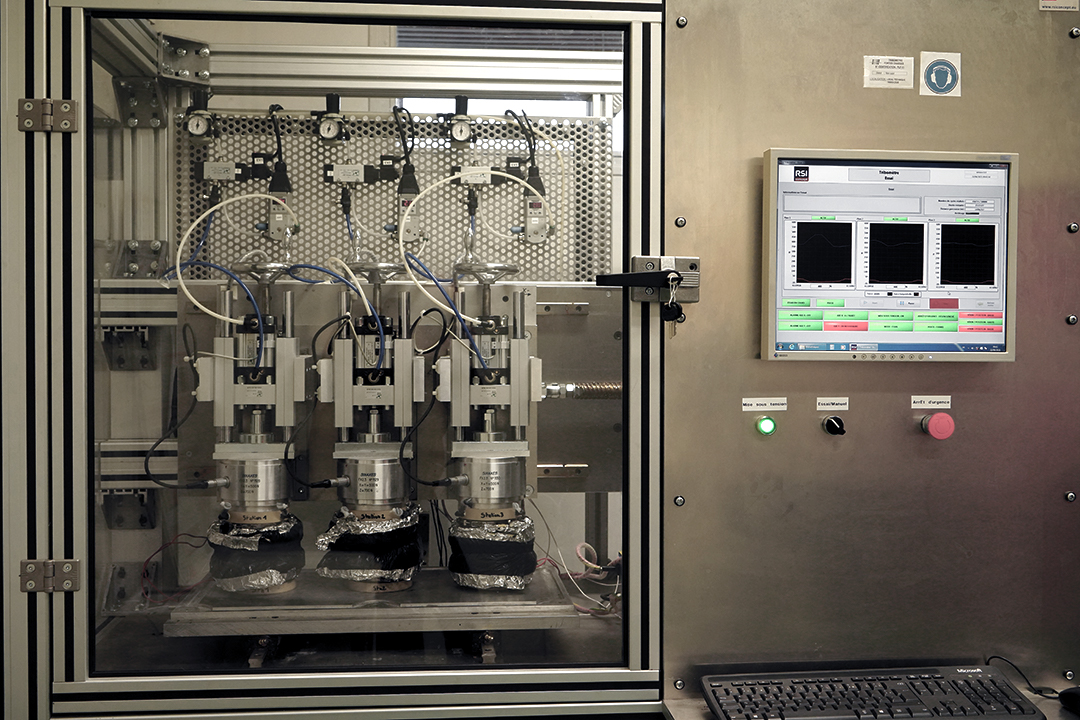

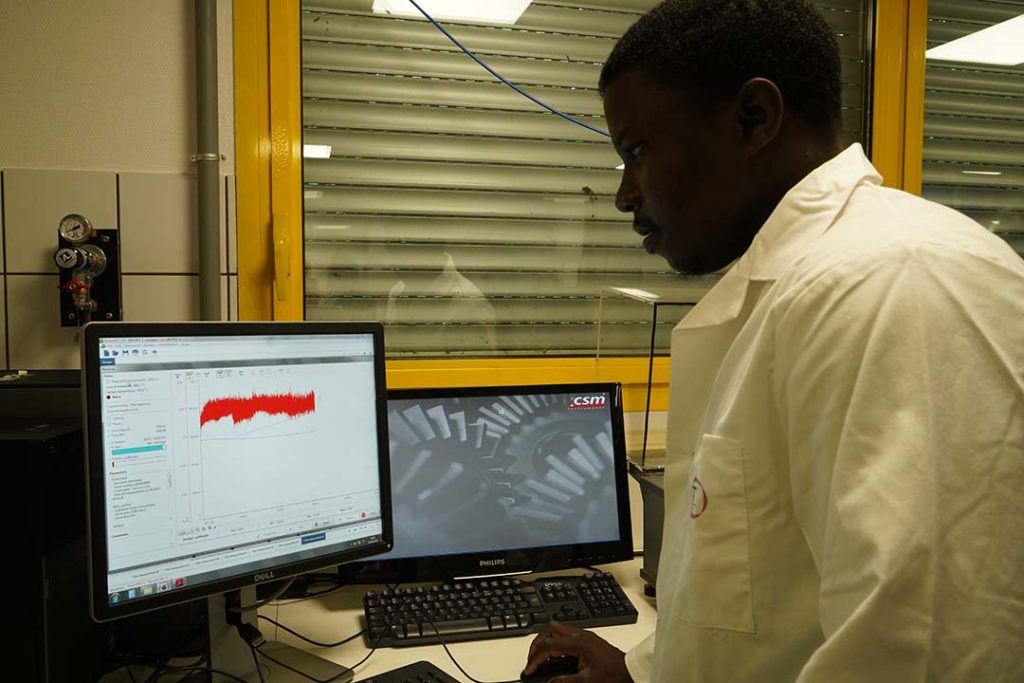

Wearing and rubbing tests

tests

Facilities of the CRITT MATÉRIAUX INNOVATION tribology platform, allow the evaluation of wearing and rubbing properties of materials and parts for several fields of activity. We are equipped with :

With these equipments, associated with its numerous facilities for surface characterization, CRITT MATÉRIAUX INNOVATION propose to support your projects for new materials development, surface treatment, comparative validation, close realistic tests conditions

A part of these tests can perform under ISO/CEI 17025 (COFRAC) accreditation. Find detail here

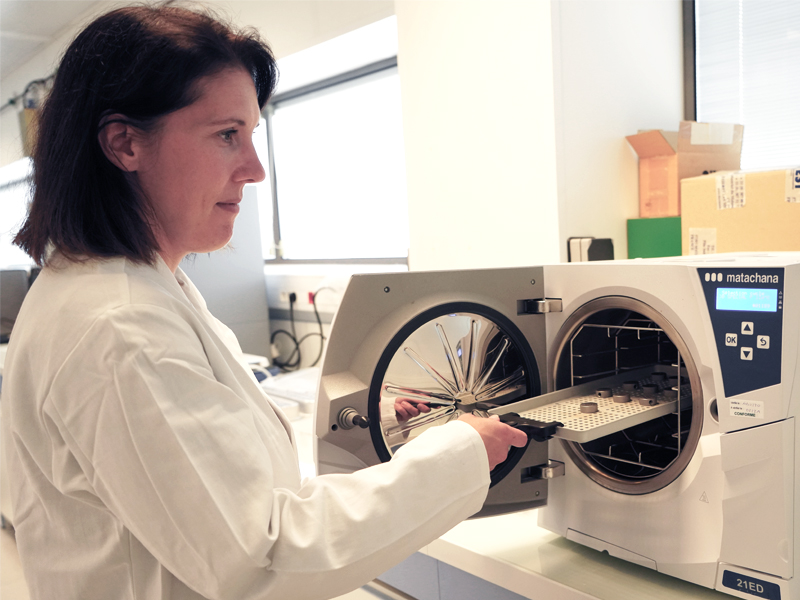

Ageing tests

tests

CRITT MATÉRIAUX INNOVATION offers you a large range of ageing tests adapted to your requiments:

A part of these tests can perform under RENAULT or AIRBUS qualification. See details here

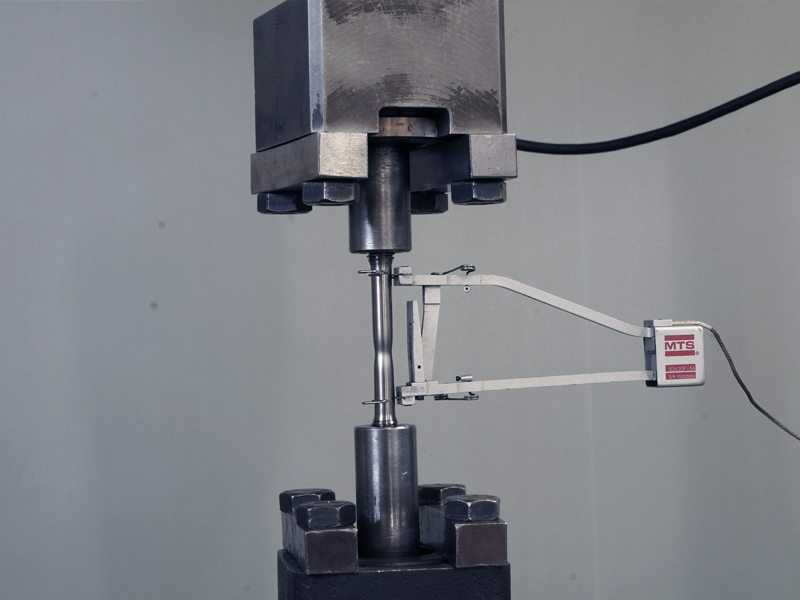

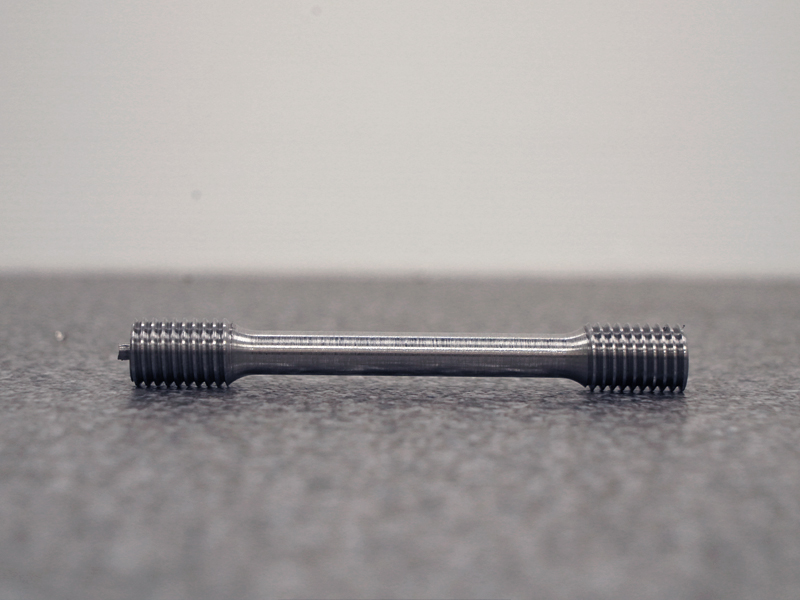

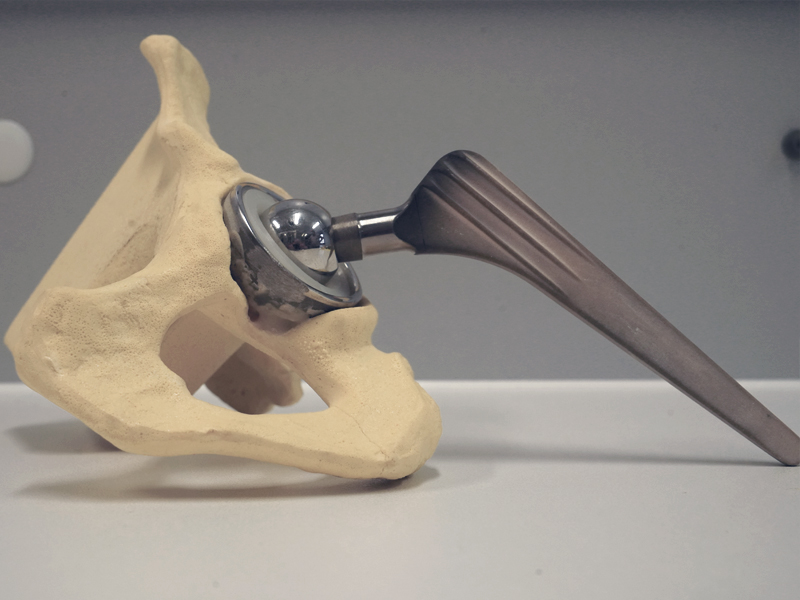

Examples of applications

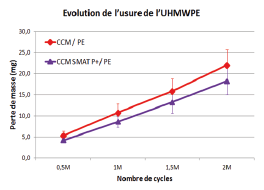

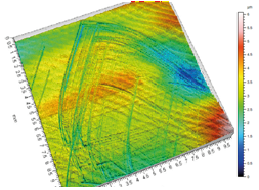

Evaluation of a Surface Mechanical Attrition Treatment (SMAT) on the scratch resistance of CoCrMo (CCM) material and the wear of a CCM/UHMWPE couple, used in hip prostheses :

Conclusion:

Decrease of scratch’s density and deepness on the metallic material as well as the mass loss on the UHMWPE antagonist.

Micro scratch test

Conventional pin-disc tribometer

High temperature tribometer

High loads tribometer

Contact:

Clémence Demangel – c.demangel@critt-mi.com

© 2025 CRITT MI – All rights reserved – Legal notice

9 rue Claude Chrétien, Campus Sup Ardenne, Bâtiment D, 08000 Charleville-Mézières | 26 Rue Lavoisier, Pôle Technologique de Champagne, Bâtiment A, 52800 Nogent