R&D Innovation

CRITT MATÉRIAUX INNOVATION Doctors and engineers support you in your R&D and innovation projects. A continuous resourcing of their knowledge, though the involvement in numerous collaborative projects, complete and efficient laboratory means, allow to carry out a reactive and effective R&D

Tribology Surface Cold Plasma Functionalization 3D printing Innovation State of the art MIM PIM CIM Wear Watch Research CIR Bibliography

R&D Innovation

CRITT MATÉRIAUX INNOVATION Doctors and engineers support you in your R&D and innovation projects. A continuous resourcing of their knowledge, though the involvement in numerous collaborative projects, complete and efficient laboratory means, allow to carry out a reactive and effective R&D.

Tribology Surface Cold Plasma Functionalization 3D printing Innovation State of the art MIM PIM CIM Wear Watch Research CIR Bibliography

Materials shaping by innovative processes

- Development for materials shaped by additive manufacturing for biomedical sector (bioresorbable polymers, and ceramics under development).

- Composite materials (metal/ceramic) by PIM process

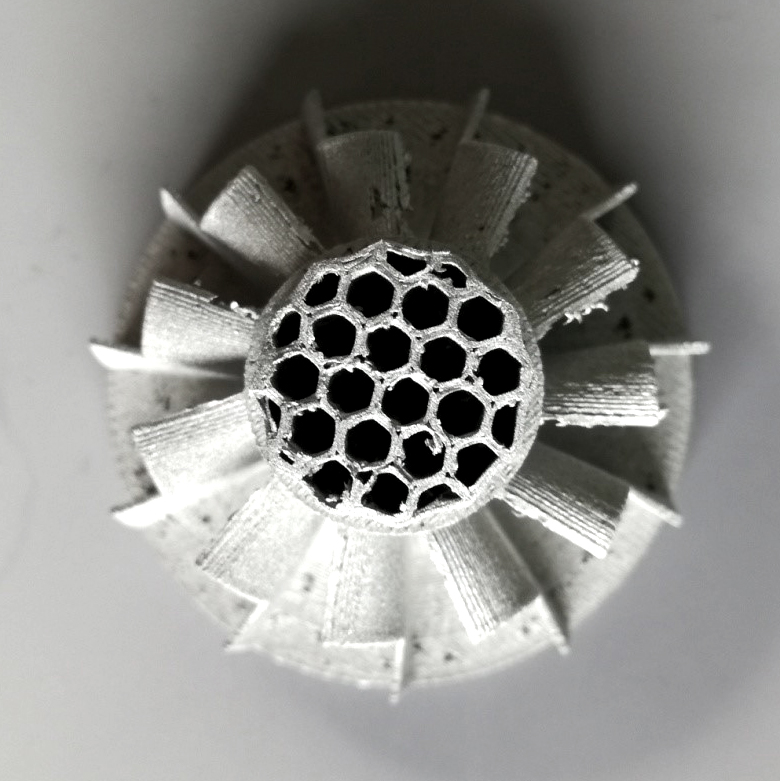

- Metallic foams elaboration by PIM process

- Metallic materials development for implantable medical devices (pure titanium, titane alloy (TA6V) and CrCoMo (F75)) by PIM process

- Development of water-based debinding (accelerator)

- Printed polymers for tribology (TPU and ABS by Freeformer)

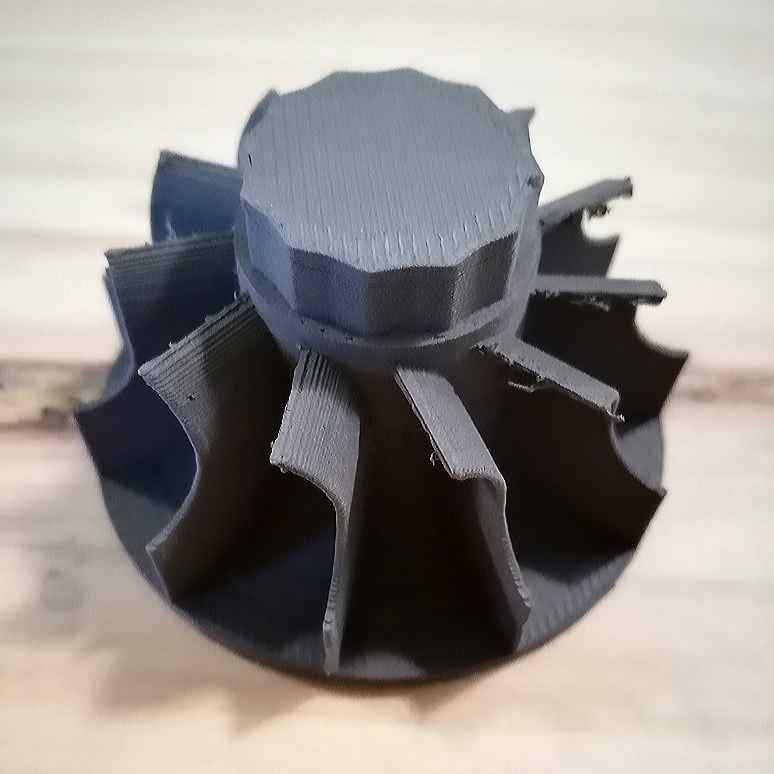

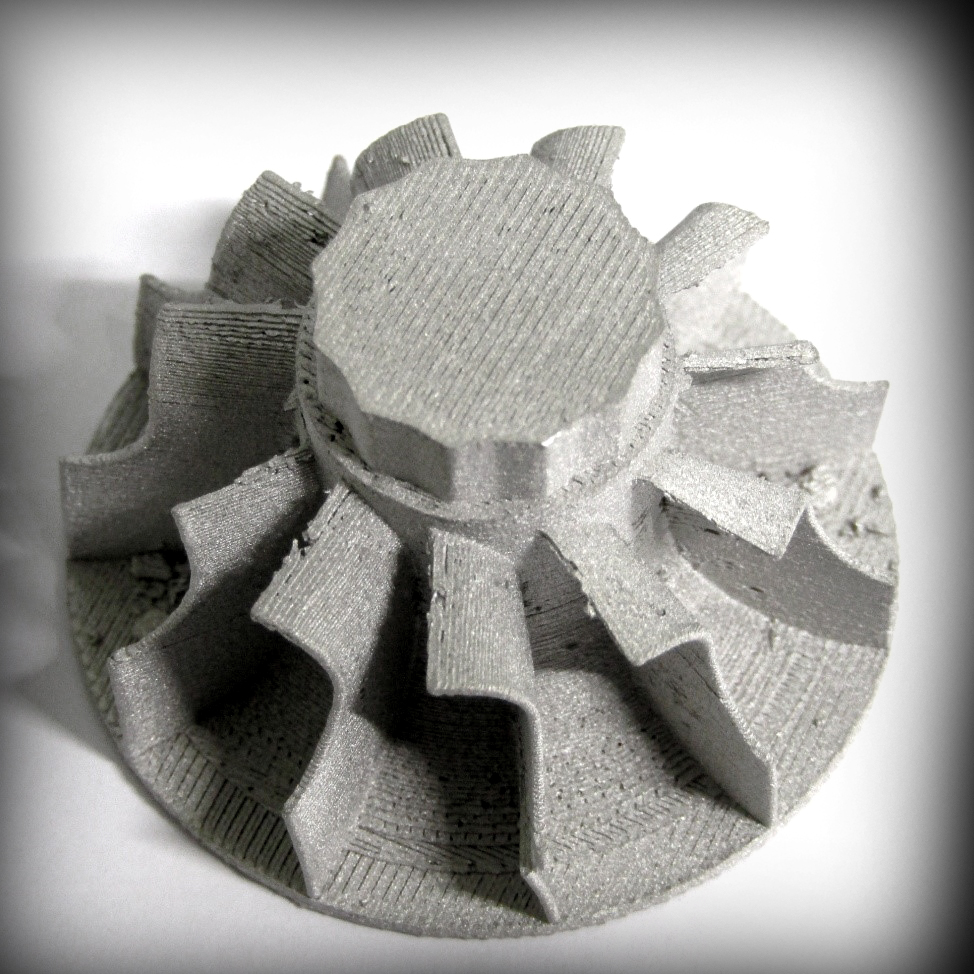

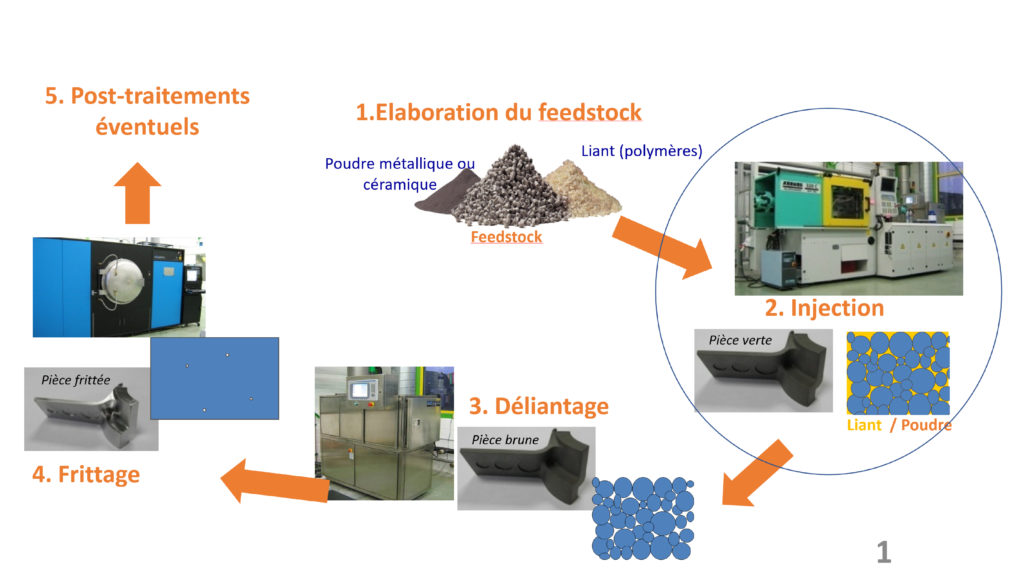

This technology consists to inject in a injection moulding machine a feedstock (mix of metallic or ceramic powder with a polymeric bind), to get a shaped part call green part. After, this part is debinded (elimination of the polymer) then sintered.

This process is adapted to:

– Based on ceramic powder (zircona, alumina…)

– Composite (several powders mixed)

– Bi-material (by co-sintering)

Injection moulding machine with multi-lift robot

Horizontal vacuum sintering furnace

“FREEFORMER” additive manufacturing machine

Ultrasonic tank Annemasse for water debinding

Ceramic debinding furnace

Others additive manufacturing machines

CRITT MATERIALS INNOVATION owns several others additive manufacturing machines, originally intended for polymers, used for its research works, notably for “PIM-Like” (PIM and additive manufacturing technologies hybridization, to obtain metallic or ceramic parts).

Catalytic debinding furnace

Ceramic sintering furnace

Surface functionalisation

TEXTOS

PRACORMAT2

CRITT MATÉRIAUX INNOVATION have various technologies:

Low pressure plasma (under vacuum)

CRITT MATÉRIAUX INNOVATION is actively working for the improvement of a cold plasma device under vacuum, allowing materials treatment, especially polymers (as biopolymers) sensitive to the temperature, chemical agents or powerful radiations effects.

This device have several plasma sources: microwaves, radiofrequency plasma and various couplings, including magnetic fields. An innovation, patented (with URCA) by CRITT MATÉRIAUX INNOVATION consists to generate a plasma exclusively inside a container, itself located inside a reactor. This technology was used to perform sterilizations treatment, but can be enlarge for others applications, as activation treatment of granular materials or thin layers by CVD.

Atmospheric pressure plasma

For a decade or so, atmospheric pressure plasmas, allowing to freeing from the vacuum, raise a growing interest, as level scientific or industrial.

CRITT MATÉRIAUX INNOVATION has various devices allowing to get plasma at ambient pressure:

- Plasma torch device (Axcys®): atmospheric plasma jet, set on a 6 axes robot.

- Manual plasma torch (Piezobrush® PZ2) from Relyon Plasma

- Plasma gun (Thermofisher, in collaboration with CNRS): plasma generation and transport in a capillary pipe for length until some meters, or splitting into several plasma secondary jets.

Plasma assited CVD coating

Chemical vapor deposition (CVD) is a chemical process used to make solid material layers with high purity and hardness levels. CRITT MATÉRIAUX INNOVATION has an evaporation device for CVD thin layers (VDM from Bronkhorst®): this system allows the transformation of phases (organometallic precursors, organic compounds or other aqueous solutions) into steam by using a carrier gas and controlled heating. Thus, thin layers CVD generation can be performed in both cases: atmospheric pressure and low pressure. Various surface treatment are complemented by:

- Measurements during the process (plasma monitoring by optical emission spectroscopy, mass spectrometry),

- An acquisition centre to record various parameters: temperature, flow, pressure, voltage, frequency…,

- Surfaces analysis (see sheet “Surface analysis”)

Wear and friction tests

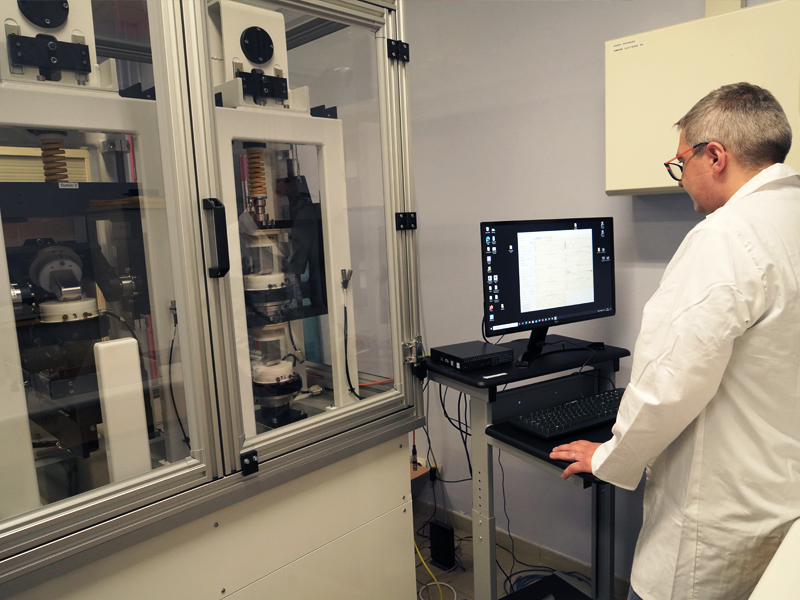

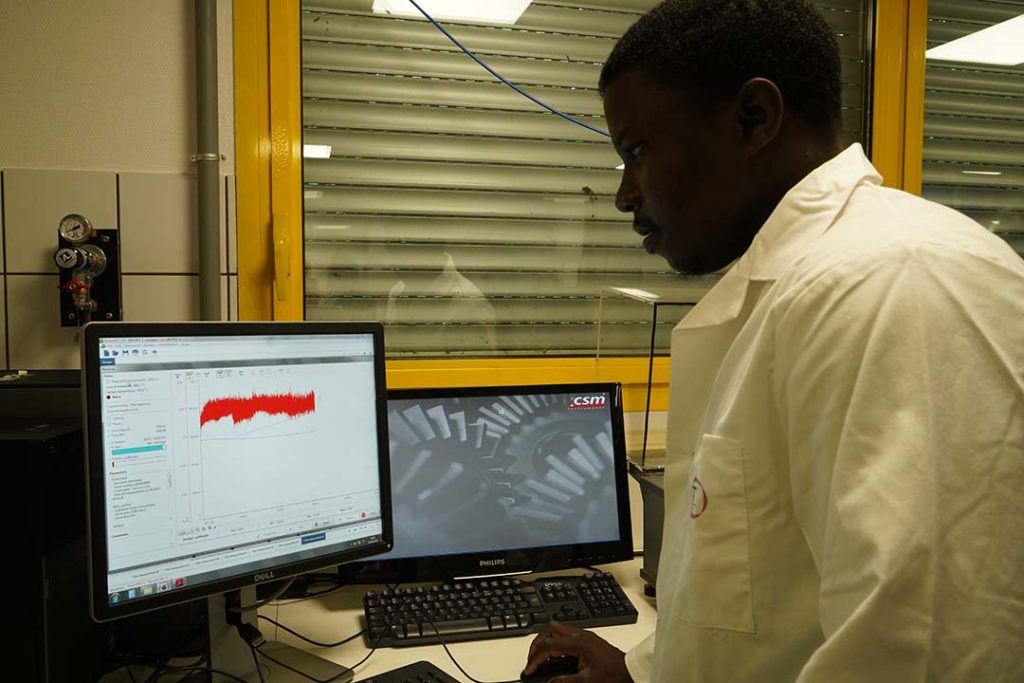

Facilities of the CRITT MATÉRIAUX INNOVATION tribology platform, allow the evaluation of wearing and friction properties of materials and parts for several fields of activity. We are equipped with:

o Standard, pin or ball-on-disc, from 1 to 20 N

o Hight temperature, until 800°C, from 1 to 20 N

o High loads with multi directional movements, until 500 N (standard ASTM F 732)

With these equipments, associated with its numerous facilities for surface characterization, CRITT MATÉRIAUX INNOVATION proposes to support your projects for new materials development, surface treatment, comparative validation, close realistic tests conditions

A part of these tests can perform under ISO/CEI 17025 (COFRAC) accreditation. Find detail here

Examples of applications

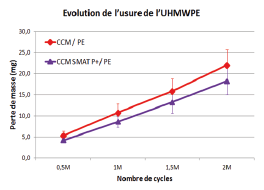

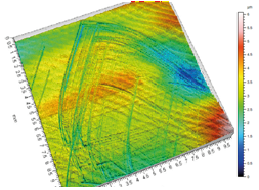

Evaluation of a Surface Mechanical Attrition Treatment (SMAT) on the scratch resistance of CoCrMo (CCM) material and the wear of a CCM/UHMWPE couple, used in hip prostheses :

Conclusion:

Decrease of scratch’s density and deepness on the metallic material as well as the mass loss on the UHMWPE antagonist.

Micro scratch test

Conventional pin-disc tribometer

High temperature tribometer

High loads tribometer

Contact:

Clémence Demangel – c.demangel@critt-mi.com

Technology watch and state of the art

Subscription to specialised magazines

Subscription to several scientific journals specialized on CRITT MATÉRIAUX INNOVATION skill fields. These journals are read and analysed by CRITT MATÉRIAUX INNOVATION staff who thus updates its skills and identify new developments likely to interest its customers

Documentary database and specialised technical data in the field of materials

Access to “Techniques de l’Ingénieur” (Engineering Techniques) and the complete collection of “ASM Handbooks”. These encyclopaedias are rich in technical data on processes and materials.

Access to database servers

Access to database servers, which can query several hundred specialised databases (bibliographic, technical data, directories, etc.).

Research and analyse patents tool

Professional tool allowing to directly query the patent databases of the European Patent Office (EPO) and the United States Patent and Trademark Office (USPTO), to extract relevant information according with a given topic, to analyse it and then to organise its monitoring.

Don’t limit your watch only to web search engines

Support for R&D projects setting up and running, and research of funding

Support for specific requests

CRITT MATÉRIAUX INNOVATION can support you in your development projects thanks to a personalised service combining its various skills:

Identification of your requirements or issues

Solutions research with our numerous databases and watching tools. (see above)

All kind of customized analyses and tests performing, with the CRITT MATÉRIAUX INNOVATION facilities.

Support for research of funding

Help to set up funding file

« Crédit Impôt Recherche » (CIR, research tax credit) and » Crédit Impôt Innovation » (CII, innovation tax credit. Only for companies located in France.

As a Technology Resource Centre (CRT), CRITT MATÉRIAUX INNOVATION is approved for the Research Tax Credit (CIR) and the Innovation Tax Credit (CII).

CIR is a tax reduction aid based on your company’s Research & Development expenditure and designed to encourage research and technological innovation.

CII is tax credit based on expenditures incurred in favour of “the design, conception of prototypes or pilot installations of new products”. Only SMEs in the European sense of the term can benefit from it.

Thus, this agreement allows to our customers which perform R&D activities to reduce the cost of performance entrusted to CRITT MATÉRIAUX INNOVATION, subject to their eligibility.

© 2025 CRITT MI – All rights reserved – Legal notice

9 rue Claude Chrétien, Campus Sup Ardenne, Bâtiment D, 08000 Charleville-Mézières | 26 Rue Lavoisier, Pôle Technologique de Champagne, Bâtiment A, 52800 Nogent